When it comes to home siding, the old saying goes, “Not All Sidings Are Created Equal.” Well, maybe it is not an old saying, per se, but it is a very relevant saying. Our expert writers here in The Lab have produced a deep dive – examining the science and art – on all types of siding. Sit back, strap on your seat belt, keep your arms and legs inside the vehicle, and enjoy an educational journey on T1-11 siding.

Table of Contents

- How Is T1-11 Siding Made?

- Protection is Key

- It’s Not As Easy as Choosing Where to Eat for the Evening

- Conclusion

How Is T1-11 Siding Made?

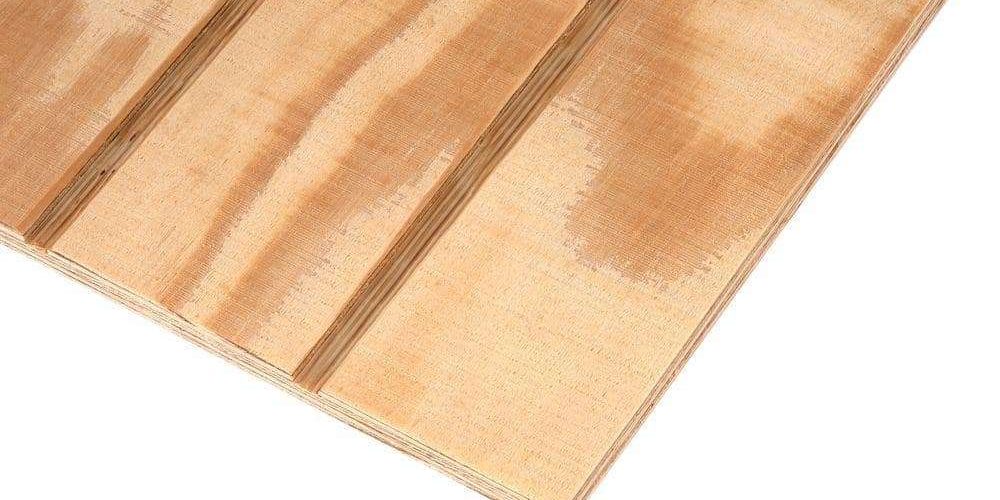

T1-11 is an engineered product, composed of plywood or OSB, and characterized by a textured facade crafted through precision milling. The panels are structured by combining resin with the wood byproduct and using high pressure to form sheets.

Once the board is pressed, a thin layer of wood veneer is applied to give the sheet visible wood grain.The T1-11 sheets are designed with grooves that emulate the classic look of vertical planks, adding the aesthetics to the board’s look. These grooves fortify the panels, lending them enhanced structural stability.

Protection is Key

In essence, T1-11 is “particle board” – made of processed wood fibers. This means that it is not as strong as if you made your siding out of a regular piece of wood.

Since T1-11 is not the strongest siding on the market, be diligent about protecting it via sealing it properly, and applying a protective stain or paint coating.

If you live in a marine environment, where the ocean air spews salt and mist into the air, another protective measure is to make sure you wash your home once every other year. Similar to your car, you want to wash the salt and other contaminants off your surface.

It’s Not As Easy as Choosing Where to Eat for the Evening

There are a number of factors at play whether or not you choose T1-11 siding for your project. First, consider cost, although engineer polymer products, such as Azek and Timbertech are more expensive in the short term, they outperform T1-11 siding in the long term.

Even with stellar maintenance, T1-11 siding’s lifespan is 10-15 years. Engineer polymer products last upwards of 30-50 years.

Next consider that without proper maintenance T1-11 siding is very susceptible to water, insects and dry rot. This combination of villains will continuously attack your home and deck. Also remember that your siding is the last line of defense to your home’s framing. Once siding is penetrated, the next victim for the villains is your wood framing.

Conclusion

The bottom line is that if you plan to not own your home very long, and budget is a concern, then T1-11 siding is a good option. If you plan to stay in your home a long time and do not like dealing with the headaches of home repair, then other options may be considered. Understanding the science behind T1-11 and how it is made, informs better decisions. Better decisions bring happiness and peace of mind. Contact Rogall + Co. to partner with you on your siding selection.