Introduction

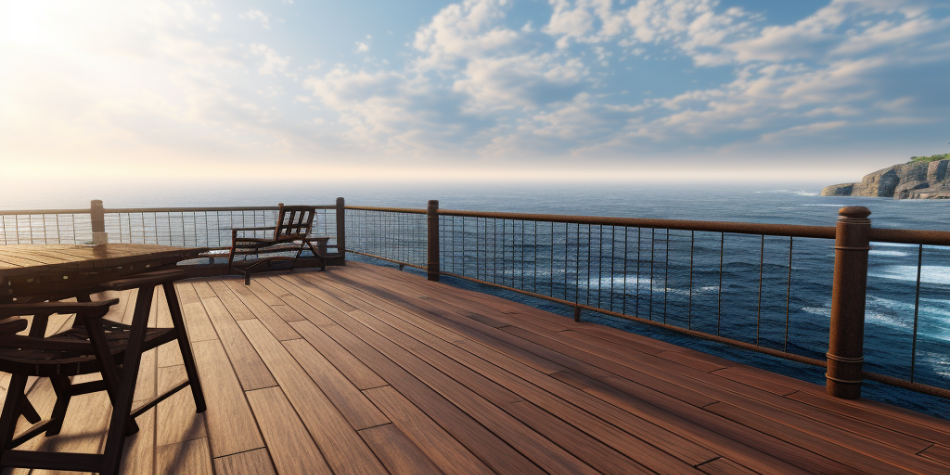

TimberTech is well known for quality. It stands for strength. It means lasting beauty. But where is it made? Let's look at its origins. Learn about its process and understand what about it makes it great by reading this article.

Table of Contents

- Introduction

- Where TimberTech Decking Begins

- The TimberTech Legacy: Quality and Sustainability

- Composite Deck Crafting: The Process Explained

- Conclusion

Where TimberTech Decking Begins

TimberTech makes more than decks. It creates outdoor escapes. It’s part of The AZEK Company. One of their primary aims is sustainability. Essentially, they believe in creating and sustaining lasting outdoor spaces. In simper terms, one might ask, what is their mission? The answer would be providing quality with innovation.

The TimberTech Legacy: Quality and Sustainability

TimberTech has roots in the U.S. It crafts decking in key locations. Here’s where the magic happens:

Wilmington, Ohio: The Start of Excellence

Wilmington is vital. It houses a major plant for the company. This facility is state-of-the-art. It shapes beloved deck lines. Materials mix here with precision. Boards come to life with care.

Scranton, Pennsylvania: The Innovation Hub

Scranton is another key spot. It focuses on high-performance decks. Here, technology meets eco-consciousness where the process of sustainability is woven in. The plant prioritizes durability where each board is made to last.

Composite Deck Crafting: The Process Explained

The company also uses a careful method. This process involves the blending and intersection of skill and tech. Here’s how it unfolds step-by-step as it undergoes a transformation keen of details to maximize "perfection".

Materials Selection: The First Step

It starts with choosing materials. Recycled wood and plastics lead. Each choice aligns with sustainability. This ensures top quality and care.

Mixing and Extrusion: The Transformation

Materials are mixed and heated. The composite is shaped. Profiles emerge from this stage. Various shapes fit different needs. The result? Unique decking boards.

Embossing and Coating: Adding Detail

Boards are then embossed. This step mimics real wood grain. Texture adds an authentic look. A polymer coat is applied. It guards against the elements, including weather and wear.

Quality Control: Ensuring Perfection

Each board faces checks. Quality control is thorough where standards are high. This means that they are able to provide and ensure top-tier results. Every deck shows this type of commitment, whether produced in one location, or produced in another. There is strict quality control and regulation to ensure that every single deck is meeting a certain standard!

Conclusion

TimberTech is made in the U.S. Ohio and Pennsylvania are home. These sites focus on quality. They ensure sustainability too. TimberTech isn’t just a product. It’s a blend of science and care.

Choose TimberTech for your home. Enjoy lasting quality and beauty. Rogall + Co. can help. Transform your space with ease. Reach out by contacting us today to receive a free consultation!